In the landscape of modern industrial automation, standard equipment often falls short when faced with complex or extreme operational conditions. Whether dealing with volatile chemical plants or sub-zero cold chain logistics, customized AGVs (Automated Guided Vehicles) are the cornerstone of ensuring both logistics efficiency and operational safety.

If you are evaluating automation solutions for specialized environments, here are the critical answers regarding our engineering capabilities.

Yes. We provide explosion-proof AGVs that comply with rigorous international safety standards.

For industries such as pharmaceuticals, coatings, or petrochemicals where volatile gases or combustible dust are present, standard AGVs pose a risk of electrical sparking. Our explosion-proof models are engineered with a "safety-first" logic:

Explosion-Proof Enclosures: All core electrical components are sealed within flameproof housings to isolate them from flammable media in the external atmosphere.

Non-Sparking Materials: External friction points utilize specialized alloys or anti-static materials to prevent sparks caused by mechanical impact.

Static Dissipation Systems: Equipped with dedicated conductive tires and grounding devices to ensure that static electricity generated during operation is discharged in real-time.

Regulatory Compliance: Units can be manufactured to meet IECEx or ATEX international certification requirements.

Absolutely. We offer dedicated deep-freeze AGV solutions specifically designed for cold chain logistics.

Extreme cold is a significant challenge for battery efficiency, hydraulic systems, and electronic components. To ensure stable operation in temperatures as low as -30°C, our cold storage AGVs feature comprehensive technical upgrades:

Defrosting & Condensation Control: The chassis integrates intelligent heating modules to prevent short circuits caused by condensation when moving between different temperature zones.

Low-Temperature Power Cells: We utilize lithium iron phosphate (LiFePO4) batteries with internal thermal management to maintain high discharge rates even in freezing conditions.

Specialized Lubrication: The entire vehicle utilizes low-viscosity hydraulic oils and specialized lubricants to prevent mechanical seizing or sluggish movement.

The customization process begins with a deep analysis of your specific site environment.

To ensure the AGVs integrate seamlessly with your production flow, we recommend providing the following details during the consultation phase:

Environmental Metrics: Specific temperature fluctuations, humidity levels, and whether there are corrosive chemicals present in the air.

Floor Conditions: Information regarding floor flatness, gradients, and the presence of oil or water, which determines navigation methods and tire material selection.

Interaction Protocols: Clarity on whether the AGVs need to interface with automated doors, elevators, or existing WMS (Warehouse Management Systems).

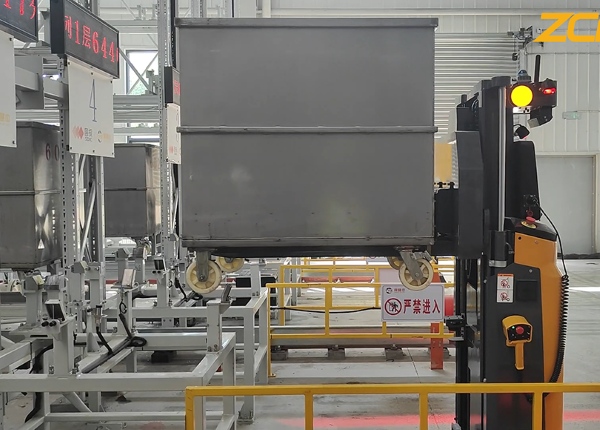

Yes. We can fully customize the physical structure of the AGV to accommodate non-standard carriers.

Not every industry uses standard wooden pallets. If your goods are stored on irregular racks, specialized containers, or oversized chassis, we can re-engineer the AGV’s handling mechanism:

Fork Dimension Customization: We adjust fork length, width, and spacing to match your specific carriers.

Diverse Loading Methods: Beyond fork-lifting, we design "load-carrying" (lifting the carrier from beneath) or "towing" configurations.

Multi-Sensor Coordination: For non-standard loads, we add additional vision or laser sensors to ensure precise identification and pick-up of irregularly shaped items.

Professional Advice: In specialized environments, maintenance frequency is typically higher than in standard settings. We recommend including a Remote Diagnostic Module in your customization package so our engineers can monitor the health of critical components in real-time.